If a new path is create outside and inside, the path is open. If only one new path is created on the outside, the path is closed. This will show you if the path is open (which might be the reason for the error). After the first cut I immediately bought it and it's paid for itself several times over on the first job we cut with it.Īs I create more jobs with MoI, I'll post the results here.Here's what I usually do to fix this problem:Ģ-Select the offending path and offset to the outside by 1/8" or so. I tried their free trial version which lets you cut a few test files to prove that it works on your machine. You can check Vectric's site, I think they have a list of the machines they can generate code for but they cover just about everything and of course they can export generic G Code too. To give you an idea, MasterCam is 50-100 times (that's not a typo) that amount depending on the options you need. It's super fast, always cuts perfectly and is only $299. For 3D cuts where normal 3 axis raster toolpaths are acceptable however, we use Cut3D from Vectric ( )

We use that for toolpathing 3D objects when there are special considerations such as features which can be machined using more efficient toolpaths to reduce cutting time or for using 4 and 5 axis CNC machines. We have MasterCam X2, which is EXTREMELY expensive and complex.

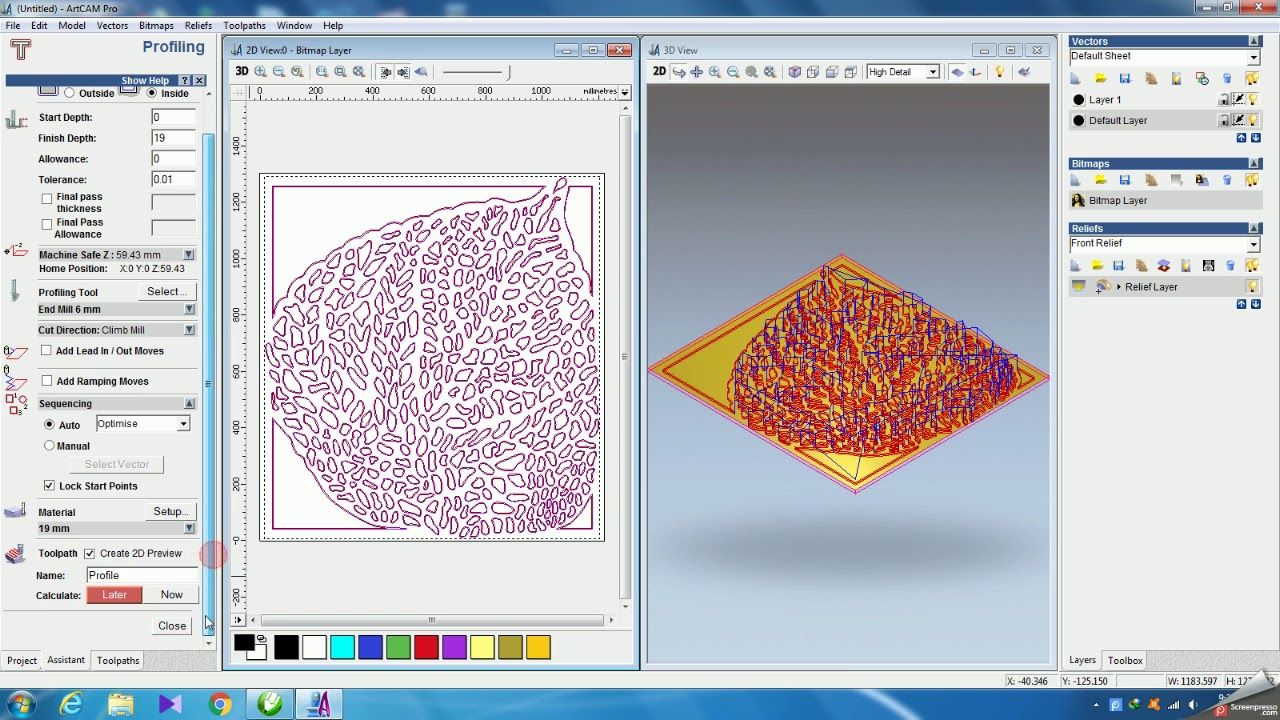

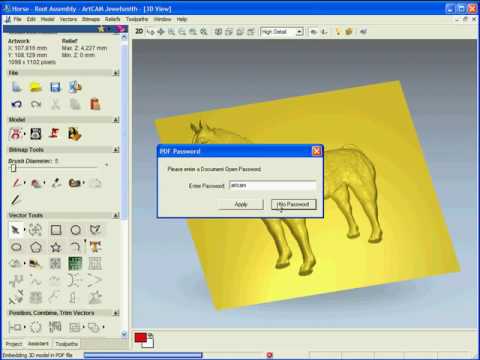

The machine time was about 30 minutes of actual cutting, figure another 5 for setup and fixturing.įor the CNC nuts out there, and you know who you are, here are the details.īit type: Onsrud 0.125" tapered ballmill (3 degree taper, 1.5" CEL)įeedrate: X+Y=180 inches per minute Z=45 inches per minuteīit Cooling: Compressed air + alcohol mistįinish Result: minor machining marks, light sanding to cleanup Great job on this software Michael, you've got a tiger by the tail! I've attached screen shots of the software involved in the process as well as a picture of the finished part. So from the first time I touched the program after the first install, I had a finished part in my hand in under 2 hours, not bad! I generated toolpaths for our CNC router from Cut3D and cut the gear out of a piece of Corian. When I was satisfied, I exported it from MoI as an stl file which I then imported into Vectric Cut3D. Within 15 minutes, I felt comfortable with the interface and it took me only a few minutes to make a nice little gear for a logo we're working on.Īfter exporting as an obj file, I imported it into Strata and did some sample renderings. I downloaded the software a couple of days ago and finally had the time to install it and play with it today. I want to start off by saying this software is phenomenal! We own just about every 3D and cad/cam package out there including 3DS Max, Maya, ZBrush, ArtCam Pro and many others and this has the best and most intuitive interface of any modeler I've seen.

0 kommentar(er)

0 kommentar(er)